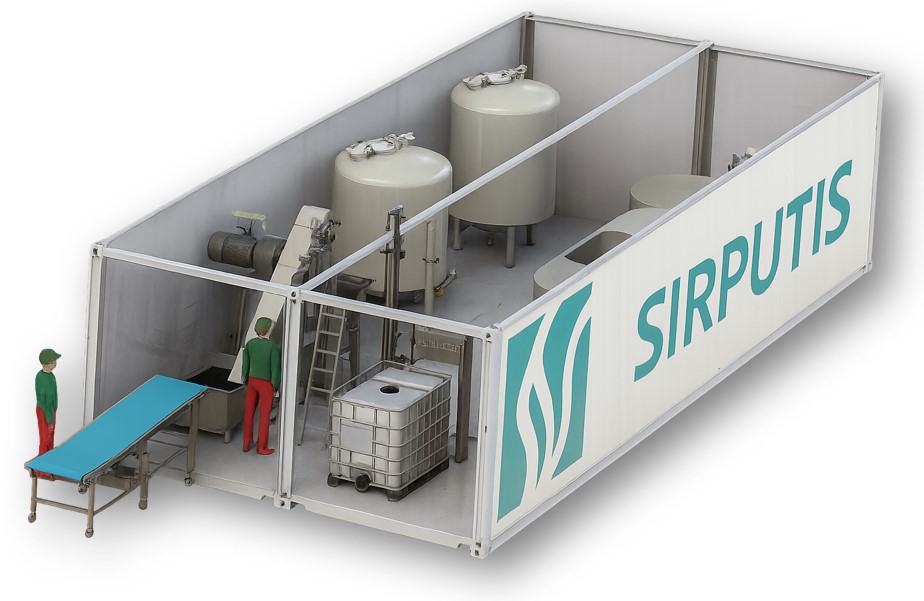

Production of high-value biostimulants in containers

Sirputis modular format equipment „Biostim 500 Compact” transforms fresh seaweed into stabilized, high-value biostimulant ingredients that support sustainable agriculture and the blue bioeconomy.

What We Deliver

Modular equipment and containerized processing units covering the full chain:

from raw seaweed → to liquid biostimulant extracts.

Works with wet or semi-dry biomass, including Sargassum, Alaria, Kappaphycus, Saccharina, Giant Kelp, and more.

Core Capabilities

-

Wet biomass intake and preparation

-

Mechanical cell disruption releasing alginate polysaccharides, fucoidan, laminarin, polyphenols

-

Stabilized liquid biostimulant output

-

Optional pulp pressing for additional product streams

Process Overview

- Seaweed disintegration into a controlled water-based slurry

- Bioactive release via mechanical cell disruption

- Separation of the liquid extract — the biostimulant product

- Pressing and optional drying of remaining pulp

Containerized extraction unit designed for

500kg/h wet weight input

-

Mass balance check (per hour):

Input = 1000 kg (100 kg DM + 900 kg water)

Output = 300 kg cake (78 kg DM + 222 kg water) + 700 kg liquid (21 kg DM + 679 kg water) = 1000 kg total

Suitable for pilot sites, coastal installations, and industrial facilities.