Biostimulant Equipment

From raw seaweed to ready-to-use biostimulant preparations.

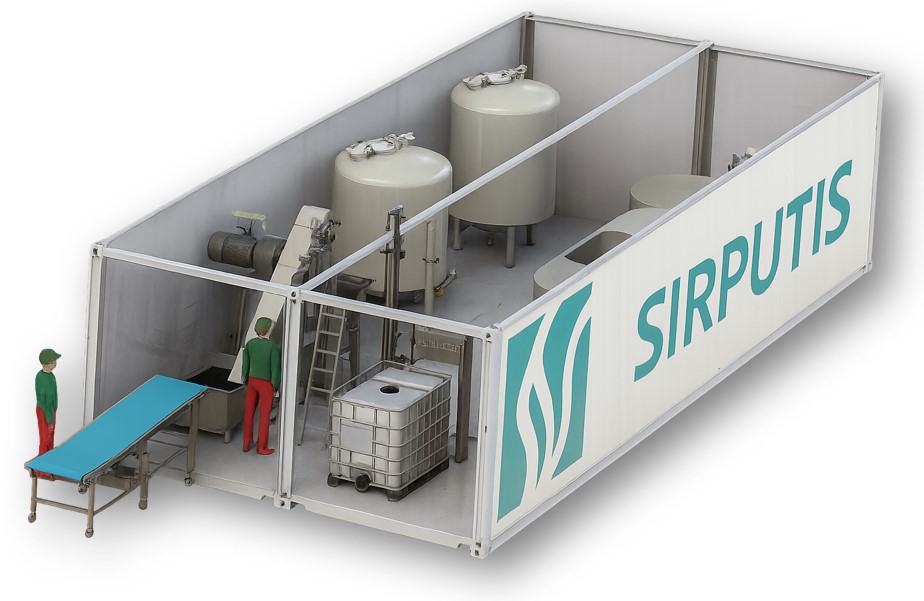

Containerized Modular Seaweed Extraction by Sirputis

Our modular system transforms freshly harvested seaweed biomass into high-value biostimulant ingredients, supporting the green transition in agriculture and related industries.

We design and manufacture equipment and modular processing systems that cover the entire technological chain — from raw seaweed to finished biostimulant products.

Process capabilities

-

Handles wet or semi-dry seaweed (including Sargassum, Alaria, Kappaphycus, Saccharina, Giant kelp, and others)

-

Input: 0.75–2.0 t/h of wet biomass

-

Operation time: 8–20 hours per day

-

Output:

-

Stabilized liquid biostimulant – 500–2,000 l/h

-

Dried granules/powder – 8–15% moisture

-

Key advantages

-

-

Sirputis mechanical cell disruption technology releases valuable alginate oligosaccharides, fucoidan, laminarin, and polyphenols from seaweed cells

-

Rapid deployment: fully operational within 6–8 months, compared to 1–1.5 years for conventional plants

-

Scalable capacity: easily expandable in 0.5 t/h increments using standardized modules — no redesign or downtime required

-

Compact footprint: 400–700 m²

-

Installed power: ~200 kW

High-Level Process Overview

The process begins with fresh seaweed biomass, which is mechanically disintegrated in a water-based slurry.

Valuable bioactive compounds are released and separated into a liquid extract, while the remaining fibrous pulp is pressed and optionally dried for further use.

Sirputis Biostim Line – Compact Seaweed Biostimulant Processing Solutions

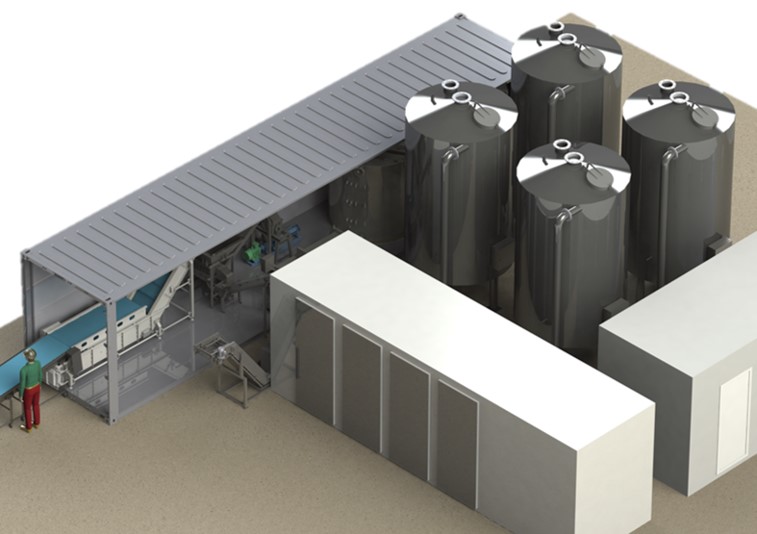

The Sirputis Biostim series offers modular, containerized process lines designed for efficiency, flexibility, and scalability, these systems support both pilot-scale and industrial operations — from coastal test sites to full production facilities.

- Biostim 500 Compact — 0.5 t/h wet input, compact modular unit

- Biostim 2000 Compact + Dryer — 2.0 t/h wet input with integrated drying system

Sirputis Biostim 500 Compact, 500kg/h wet weight input

General Assumptions

| Parameter | Unit | Value |

| Line capacity (wet seaweed input) | kg/h | 500 |

| Typical solids content in fresh Asco | % | 20 |

| Dry matter in incoming seaweed | kg/h | 100 |

| Added process water (for slurry preparation) | kg/h | 500 |

| Total feed slurry | kg/h | 1000 |

Pressing / Fractionation Balance

| Parameter | Unit | Value |

| Dry matter retained in pressed cake | % of input DM | 78 |

| Dry matter to cake | kg/h | 78 |

| Pressed cake dry solids | % | 26 |

| Pressed cake output | kg/h | 300 |

| Liquid phase output | kg/h | 700 |

| Dry matter to liquid phase | kg/h | 21 |

| Solids concentration in liquid phase | % | ≈3.0 |

Mass balance check (per hour):

Input = 1000 kg (100 kg DM + 900 kg water)

Output = 300 kg cake (78 kg DM + 222 kg water) + 700 kg liquid (21 kg DM + 679 kg water) = 1000 kg total

Annual Operation (8 h × 250 days = 2000 h/year)

| Parameter | Unit | Value |

| Operating hours per year | h/year | 2000 |

| Annual throughput (wet) | t/year | 1000 |

| Annual dry matter processed | t/year | 200 |

| Annual pressed cake DM | t/year | 156 |

| Annual liquid phase DM | t/year | 42 |

| Approx. liquid extract volume (1 kg ≈ 1 L) | L/t (WW) | ≈1400 |

| Total annual liquid extract volume | L/year | ≈1,400,000 |

Sirputis Biostim 2000 Compact + Dryer (2.0 t/h wet input)

Balanced Technical & Economic Summary

General assumptions

| Parameter | Unit | Value |

| Line capacity (wet seaweed input) | kg/h | 2,000 |

| Typical solids in fresh Asco | % | 20 |

| Dry matter in incoming seaweed | kg/h | 400 |

| Added process water (for slurry prep) | kg/h | 2,000 |

| Total feed slurry | kg/h | 4,000 |

Pressing / fractionation balance (per hour)

| Parameter | Unit | Value |

| DM retained in pressed cake | % of input DM | 78% (adjusted from 79% to balance) |

| Dry matter to cake | kg/h | 312 |

| Pressed cake dry solids (DS) | % | 26 |

| Pressed cake output | kg/h | 1,200 |

| Liquid phase output | kg/h | 2,800 |

| Dry matter to liquid phase | kg/h | 88 |

| Solids concentration in liquid | % (m/m) | ≈3.14% (88/2,800) |

Balance check (per hour):

Input = 4,000 kg (400 kg DM + 3,600 kg water)

Output = 1,200 kg cake (312 kg DM + 888 kg water) + 2,800 kg liquid (88 kg DM + 2,712 kg water) = 4,000 kg

DM in = 400 kg; DM out = 312 + 88 = 400 kg

Annual operation (8 h × 250 days = 2,000 h/year)

| Parameter | Unit | Value |

| Operating hours per year | h/year | 2,000 |

| Annual throughput (wet) | t/year | 4,000 |

| Annual DM processed | t/year | 800 |

| Annual cake DM | t/year | 624 (312 kg/h × 2,000 h) |

| Annual liquid-phase DM | t/year | 176 (88 kg/h × 2,000 h) |

| Approx. liquid extract volume (1 kg ≈ 1 L) | L/t (WW) | ≈1,400 |

| Total annual liquid extract volume | L/year | ≈5,600,000 |

Commercial & operational benefits

Flexible & Scalable Design

-

Modular, containerized units for rapid deployment and easy capacity expansion

-

Stainless steel tanks (5–15 m³) with integrated CIP, agitation, and sensors

-

PLC/HMI automation with remote monitoring and predictive maintenance

Business Case

-

Multi-stream revenue model: liquid biostimulant plus solid co-products (pulp or dried powder)

-

Compact, relocatable setup — ideal for coastal or port-based operations

-

Year-round processing of multiple seaweed species (Ascophyllum, Laminaria, Fucus, etc.)

-

Low initial CAPEX with a clear path for capacity scaling as demand grows

-

Process Line

-

Raw Material Handling

- Reception, washing, chopping, and pre-treatment

- Wet stabilization to preserve bioactive compounds

-

Extraction System

- Mechanical and/or enzymatic cell disruption

- Thermal or cold extraction — adjustable for specific compounds

Filtration & Clarification

- Solid–liquid separation and fine filtration modules

- Integrated press and liquid-phase management

-

- Drying (for Biostim 2000 Compact + Dryer)

- Continuous or batch drying for solid or pulp co-products

- Energy-efficient operation with temperature control and full automation

System Features

- Adaptable to various seaweed species and processing conditions

- Modular and scalable — from pilot to industrial scale

- Energy-efficient and low-maintenance operation

- Designed to meet food-grade or agricultural production standards

- Optional advanced automation and temperature regulation

Applications

Sirputis equipment enables production of liquid and powdered seaweed biostimulants used in:

-

Agriculture – enhances plant growth, nutrient uptake, and stress resistance

-

Horticulture – improves root development, yield, and soil health

-

Soil restoration & organics – valorization of solid residues as natural soil amendments

Contact Us

Interested in launching or scaling your seaweed biostimulant production?

Contact our engineering team to discuss your project requirements and ROI model.

-

Where We Deliver