Biostimulant Equipment

From raw seaweed to ready-to-use biostimulant preparations.

Containerized Modular Seaweed Extraction by Sirputis

Our modular system transforms freshly harvested seaweed biomass into high-value biostimulant ingredients, supporting the green transition in agriculture and related industries.

We design and manufacture equipment and modular processing systems that cover the entire technological chain — from raw seaweed to finished biostimulant products.

Process capabilities

-

Handles wet or semi-dry seaweed (including Sargassum, Alaria, Kappaphycus, Saccharina, Giant kelp, and others)

-

Input: 0.75–2.0 t/h of wet biomass

-

Operation time: 8–20 hours per day

-

Output:

-

Stabilized liquid biostimulant – 500–2,000 l/h

-

Dried granules/powder – 8–15% moisture

-

Key advantages

-

-

Sirputis mechanical cell disruption technology releases valuable alginate oligosaccharides, fucoidan, laminarin, and polyphenols from seaweed cells

-

Rapid deployment: fully operational within 6–8 months, compared to 1–1.5 years for conventional plants

-

Scalable capacity: easily expandable in 0.5 t/h increments using standardized modules — no redesign or downtime required

-

Compact footprint: 400–700 m²

-

Installed power: ~200 kW

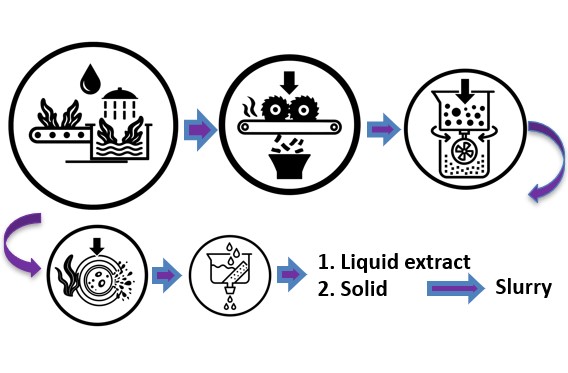

High-Level Process Overview

The process begins with fresh seaweed biomass, which is mechanically disintegrated in a water-based slurry.

Valuable bioactive compounds are released and separated into a liquid extract, while the remaining fibrous pulp is pressed and optionally dried for further use.

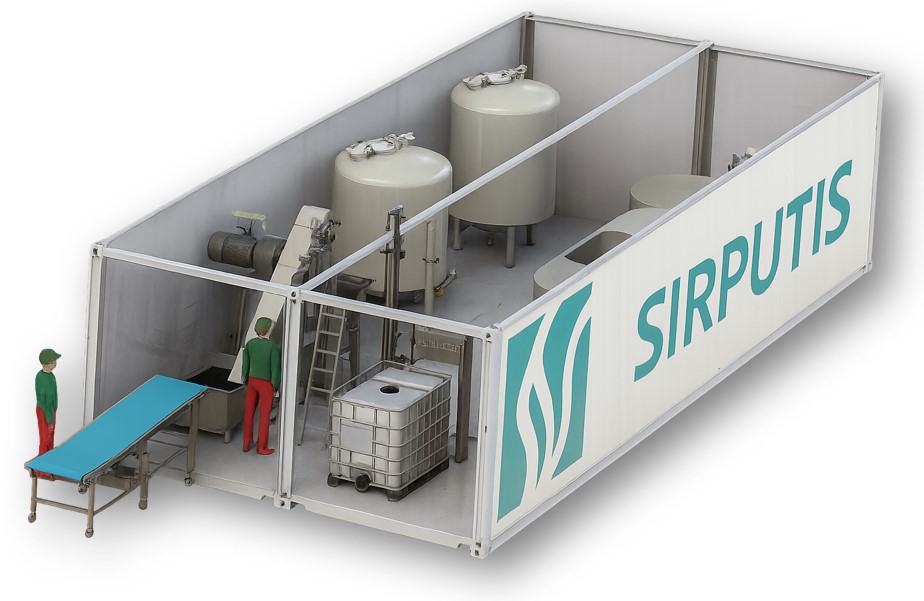

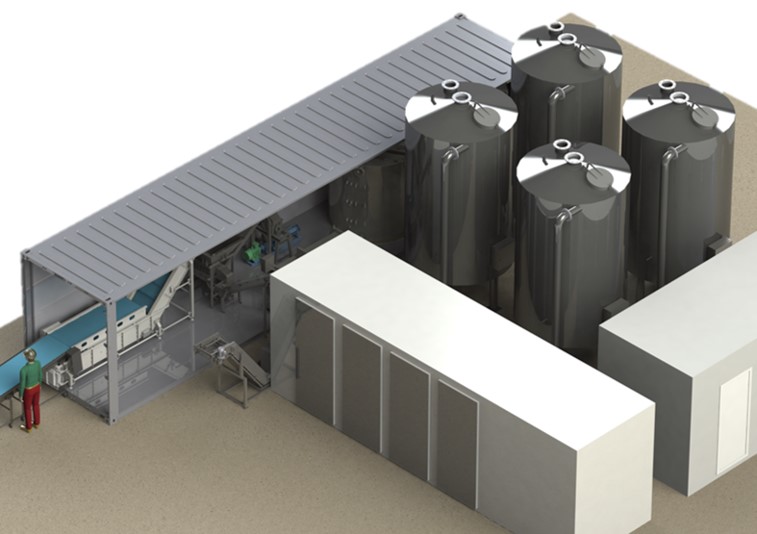

Sirputis Biostim Line – Compact Seaweed Biostimulant Processing Solutions

The Sirputis Biostim series offers modular, containerized process lines designed for efficiency, flexibility, and scalability, these systems support both pilot-scale and industrial operations — from coastal test sites to full production facilities.

- Biostim 500 Compact — 0.5 t/h wet input, compact modular unit

- Biostim 2000 Compact + Dryer — 2.0 t/h wet input with integrated drying system

Sirputis Biostim 500 Compact, 500kg/h wet weight input

General Assumptions

| Parameter | Unit | Value |

| Line capacity (wet seaweed input) | kg/h | 500 |

| Typical solids content in fresh Asco | % | 20 |

| Dry matter in incoming seaweed | kg/h | 100 |

| Added process water (for slurry preparation) | kg/h | 500 |

| Total feed slurry | kg/h | 1000 |

Pressing / Fractionation Balance

| Parameter | Unit | Value |

| Dry matter retained in pressed cake | % of input DM | 78 |

| Dry matter to cake | kg/h | 78 |

| Pressed cake dry solids | % | 26 |

| Pressed cake output | kg/h | 300 |

| Liquid phase output | kg/h | 700 |

| Dry matter to liquid phase | kg/h | 21 |

| Solids concentration in liquid phase | % | ≈3.0 |

Mass balance check (per hour):

Input = 1000 kg (100 kg DM + 900 kg water)

Output = 300 kg cake (78 kg DM + 222 kg water) + 700 kg liquid (21 kg DM + 679 kg water) = 1000 kg total

Annual Operation (8 h × 250 days = 2000 h/year)

| Parameter | Unit | Value |

| Operating hours per year | h/year | 2000 |

| Annual throughput (wet) | t/year | 1000 |

| Annual dry matter processed | t/year | 200 |

| Annual pressed cake DM | t/year | 156 |

| Annual liquid phase DM | t/year | 42 |

| Approx. liquid extract volume (1 kg ≈ 1 L) | L/t (WW) | ≈1400 |

| Total annual liquid extract volume | L/year | ≈1,400,000 |

Sirputis Biostim 2000 Compact + Dryer (2.0 t/h wet input)

Balanced Technical & Economic Summary

General assumptions

| Parameter | Unit | Value |

| Line capacity (wet seaweed input) | kg/h | 2,000 |

| Typical solids in fresh Asco | % | 20 |

| Dry matter in incoming seaweed | kg/h | 400 |

| Added process water (for slurry prep) | kg/h | 2,000 |

| Total feed slurry | kg/h | 4,000 |

Pressing / fractionation balance (per hour)

| Parameter | Unit | Value |

| DM retained in pressed cake | % of input DM | 78% (adjusted from 79% to balance) |

| Dry matter to cake | kg/h | 312 |

| Pressed cake dry solids (DS) | % | 26 |

| Pressed cake output | kg/h | 1,200 |

| Liquid phase output | kg/h | 2,800 |

| Dry matter to liquid phase | kg/h | 88 |

| Solids concentration in liquid | % (m/m) | ≈3.14% (88/2,800) |

Balance check (per hour):

Input = 4,000 kg (400 kg DM + 3,600 kg water)

Output = 1,200 kg cake (312 kg DM + 888 kg water) + 2,800 kg liquid (88 kg DM + 2,712 kg water) = 4,000 kg

DM in = 400 kg; DM out = 312 + 88 = 400 kg

Annual operation (8 h × 250 days = 2,000 h/year)

| Parameter | Unit | Value |

| Operating hours per year | h/year | 2,000 |

| Annual throughput (wet) | t/year | 4,000 |

| Annual DM processed | t/year | 800 |

| Annual cake DM | t/year | 624 (312 kg/h × 2,000 h) |

| Annual liquid-phase DM | t/year | 176 (88 kg/h × 2,000 h) |

| Approx. liquid extract volume (1 kg ≈ 1 L) | L/t (WW) | ≈1,400 |

| Total annual liquid extract volume | L/year | ≈5,600,000 |

Commercial & operational benefits

Flexible & Scalable Design

-

Modular, containerized units for rapid deployment and easy capacity expansion

-

Stainless steel tanks (5–15 m³) with integrated CIP, agitation, and sensors

-

PLC/HMI automation with remote monitoring and predictive maintenance

Business Case

-

Multi-stream revenue model: liquid biostimulant plus solid co-products (pulp or dried powder)

-

Compact, relocatable setup — ideal for coastal or port-based operations

-

Year-round processing of multiple seaweed species (Ascophyllum, Laminaria, Fucus, etc.)

-

Low initial CAPEX with a clear path for capacity scaling as demand grows

Investment & Revenue Example:

| Model | Wet Input | CAPEX | Annual Throughput | Est. Revenue* |

|---|---|---|---|---|

| Biostim 500 Compact | 0.5 t/h | ~€300,000 | 1,000 t/year | ~€2.1M/year |

| Biostim 2000 Compact + Dryer | 2.0 t/h | ~€1,000,000 | 4,000 t/year | ~€8.4M/year |

*Based on 1.4 m³ liquid extract per ton of wet seaweed at €1.5/L (3% DM).

Contact Us

Interested in launching or scaling your seaweed biostimulant production?

Contact our engineering team to discuss your project requirements and ROI model.

- Process Line

Raw Material Handling

- Reception, washing, chopping, and pre-treatment

- Wet stabilization to preserve bioactive compounds

Extraction System

- Mechanical and/or enzymatic cell disruption

- Thermal or cold extraction — adjustable for specific compounds

Filtration & Clarification

- Solid–liquid separation and fine filtration modules

- Integrated press and liquid-phase management

Drying (for Biostim 2000 Compact + Dryer)

- Continuous or batch drying for solid or pulp co-products

- Energy-efficient operation with temperature control and full automation

System Features

- Adaptable to various seaweed species and processing conditions

- Modular and scalable — from pilot to industrial scale

- Energy-efficient and low-maintenance operation

- Designed to meet food-grade or agricultural production standards

- Optional advanced automation and temperature regulation

Applications

Sirputis equipment enables production of liquid and powdered seaweed biostimulants used in:

-

Agriculture – enhances plant growth, nutrient uptake, and stress resistance

-

Horticulture – improves root development, yield, and soil health

-

Soil restoration & organics – valorization of solid residues as natural soil amendments

-

Where We Deliver